Membrane Bio-Reactor

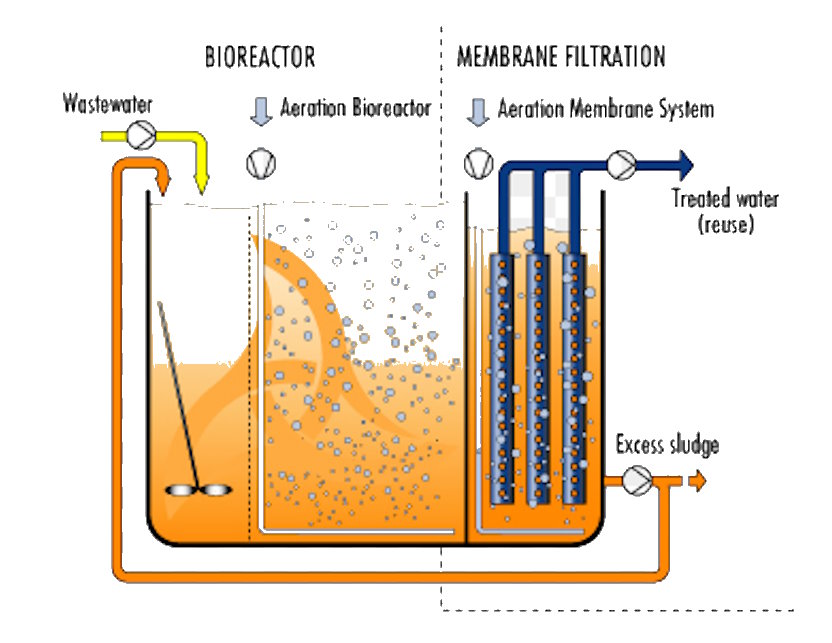

• A MEMBRANE BIOREACTOR (MBR) is a process which combines a microfiltration or ultrafiltration membrane unit with a suspended growth bioreactor, and is now widely used in both municipal and industrial Waste Water Treatment Plants.

• The Membrane Bioreactor (MBR) couples an activated sludge reactor with a membrane filtration unit.

• MBR is a very efficient treatment with several advantages over conventional activated sludge technologies.

• MBR is used for both municipal and industrial wastewater treatment applications.

• Two MBR configurations are available (submerged and side stream).

• PCI Membranes can help you choosing the proper solution for your plant as we are one of the few suppliers offering both.

• In the MBR process, membranes act as a solid-liquid separation device, keeping the biomass within the bioreactor before discharging the treated effluent to the nature.

• Basically, they take the place of clarifiers used in the conventional activated sludge (CAS) process.

• MBR is the low-footprint, high-effluent-quality solution to your wastewater treatment needs. It can be used to upgrade existing WWTPs as well as to build new, state-of-the-art facilities.

• As one of the few suppliers offering both submerged and side stream membranes, we are glad to support you! Our experts will help you to find the MBR as the solution which is the most suitable to your specific case.

MBBR- Moving Bed Biofilm Reactor

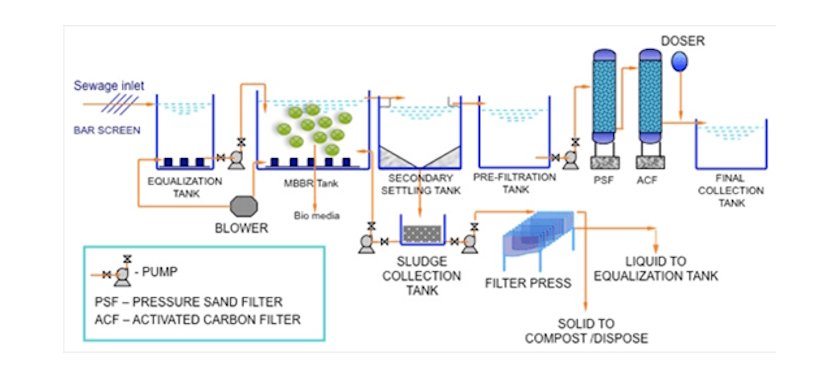

• Moving bed biofilm reactor (MBBR) is a biological technology used for wastewater treatment process suitable for municipal and industrial application.

• Another common name is moving bed film reactor

• MBBR offer an economical solution for wastewater treatment. STP MBBR technology is the use of a moving bed biofilm reactor in sewage treatment plants.

• The technology is used to separate organic substances, nitrification and denitrification.

• MBBR design is made of an activated sludge aeration system. The sludge is collected on the plastic carriers which have a large internal surface area.

• The surface area in the carriers optimizes the contact of water, air, and the bacteria. MBBR activated sludge is the application of MBBR media to an overloaded treatment plant when upgrading.

• The quantity of biomass plays a big role in the removal efficiency of the MBBR system, it can be increased through the volume of carriers per unit.

• The carrier’s performance needs to be proven for specific wastewater treatment for application of different cases.

• Design of a water treatment plant should not be based on assumption or estimation but the correct material should be used for the carrier and the volume required calibrated.

• MBBR technology is effective for wastewater treatment if the regulation concerning the effluent water discharge.

• The system is flexible in its application and can easily be relocated. Wastewater treatment as required for ecological reasons can be done using the MBBR.

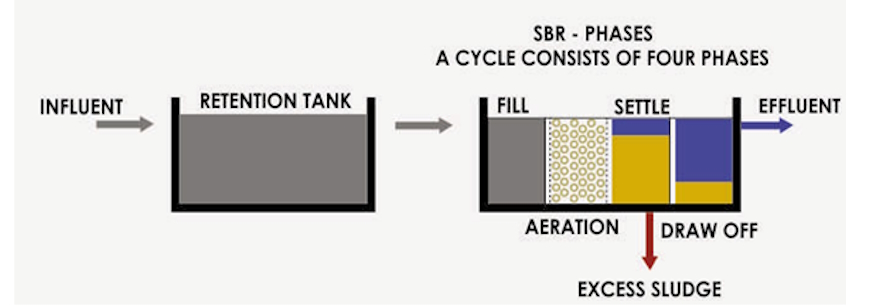

SBR- Sequential Batch Reactor

- The steps involved here are.

- Filling

- Aeration

- Settling

- Decanting

- Idling

- Sludge drying