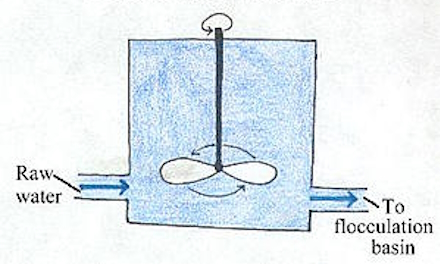

Flash Mixer

• Flash Mixer is a unit operation for treatment of raw water intake;

• it is used in water treatment and wastewater treatment.

• It helps in removal of Heavy Particles and reduces Suspended solids.

• After screening out debris and testing the raw water, water treatment really begins at the flash mix chamber.

• Here, chemicals are added to the water, primarily to aid in coagulation and flocculation.

• In the flash mixer, the water is agitated violently for a short period of time before being released into the flocculation basin.

• The duration of mixing in the flash mix chamber is carefully controlled and is usually between thirty seconds and one minute.

• If the water is mixed for less than thirty seconds, then the chemicals will not be properly mixed into the water.

• But if the water is mixed for more than sixty seconds, then the blades will shear the newly forming floc back into smaller particles.

• When determining the length of time that water must spend in the flash mix chamber, flow rates must be calculated.

• The volume of the flash mix chamber and the amount of flow determine the contact time.

Target Impurities: –

1. TSS

2. Turbidity

3. BOD

4. Colloidal Particles

5. Partial Color

Advantages: –

1. Water is quickly mixed

2. Low Cost and No Maintenance

3. Fast Sedimentation

Flocculator

• Flocculation is a process by which colloidal particles come out of suspension to sediment in the form of floc or flake, either spontaneously or due to the addition of a clarifying agent.

• The action differs from precipitation in that, prior to flocculation, colloids are merely suspended, under the form of a stable dispersion (where the internal phase (solid) is dispersed throughout the external phase (fluid) through mechanical agitation) and are not truly dissolved in solution.

• Coagulation and flocculation are important processes in water treatment with coagulation aimed to destabilize and aggregate particles through chemical interactions between the coagulant and colloids, and flocculation to sediment the destabilized particles by causing their aggregation into floc.